07799847899

About Us

Adept Tooling Limited was conceived by four partners in 2003 with over 50 years experience within the design and manufacturing of industrial grade cutting, grinding and polishing tools.

Based in North Wales, Adept Tooling Limited serve clients across the UK and Europe specialising in a diverse range of industries.

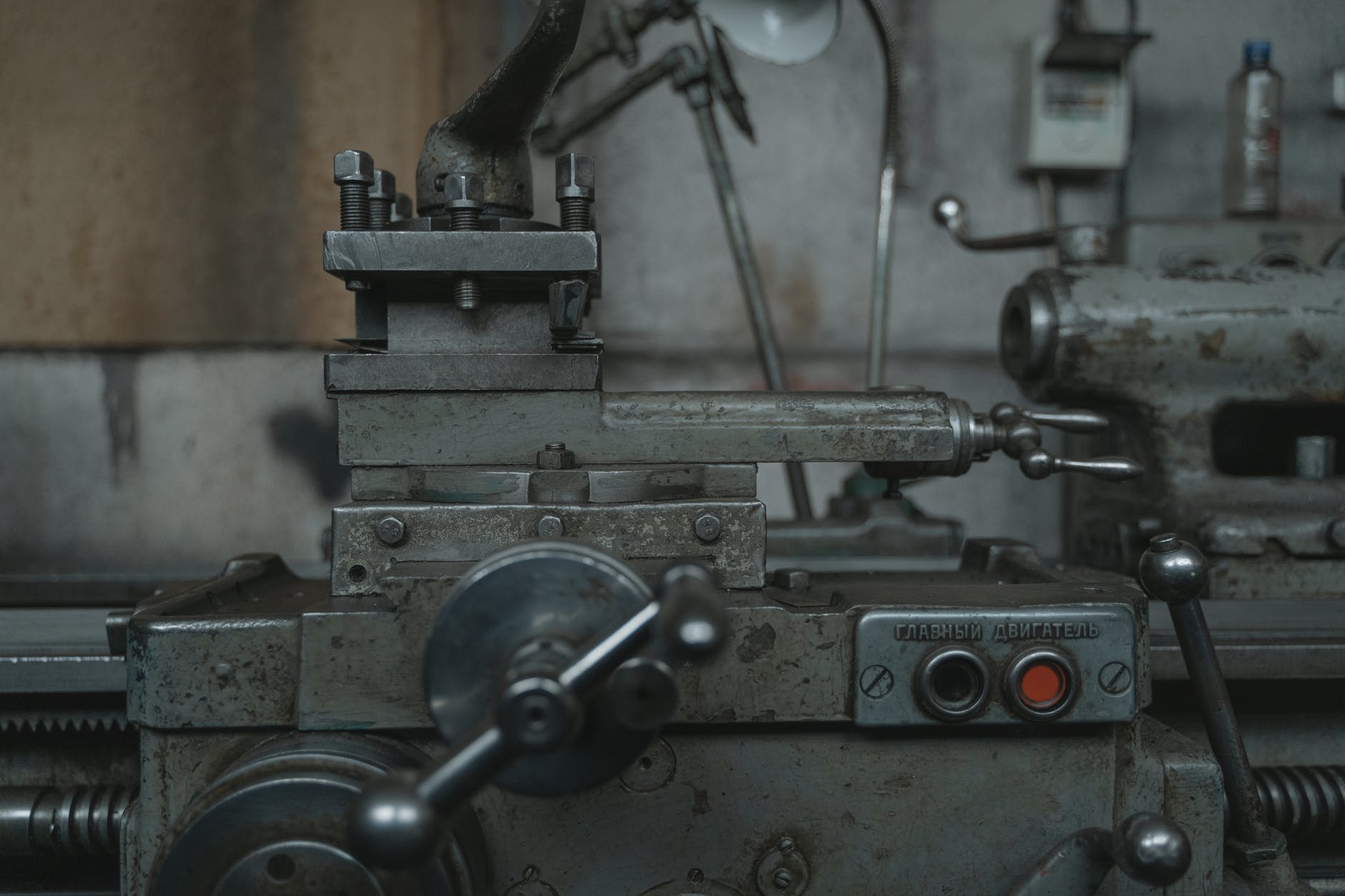

Adept Tooling is mainly a bespoke manufacturer of electroplated tools but we can offer a variety of other services such as resin bond wheels upon request.

Services

Adept Tooling offers a tailored approach based on our client’s requirements and can assist in any part of the manufacturing process.

Our primary services are as follows:

- Our most popular service is the strip and replate: our clients provide us with an exhausted tool (blade/ form wheel/ file) where we chemically remove existing diamond, clean surface for application and then apply new diamond grit to specification — this is both a cost effective and environmentally friendly solution

- Client provides us with a blank tool (blade/ form wheel/ file) and we will clean surface for application and then apply new diamond grit to specification.

- Our most comprehensive service where the client will provide us with a design in CAD format and we will manufacture the blank tool to design, clean surface for application and then apply new diamond grit to specification.

Products and Applications

At Adept Tooling we supply a range of bespoke cutting and grinding tools for various end use applications as described in the following list:

- Continuous or slotted rim 50mm to 500mm blades for GRP/ composites industry including noise reduction.

- Form wheels for grinding steel, carbide, ceramics and glass.

- Stainless steel tubes of various diameters to the glass industry.

- Saw blades for cutting and forming brake linings.

We can electroplate both stainless steel and lead free steel bodies with some aluminium applications.

Case Studies

- Strip and replate — a company within the medical equipment industry:

- On a continuous monthly order we can receive up to 5000 steel tubes which come in a range of dimensions to which we coat a 3mm tip in a medium to fine grade diamond grit to drill through glass surfaces. Based on the above example our receipt of order to shipment would be 21 days.

- Manufacture blank tool to design and apply diamond grit to specification — helmet manufacturing company:

- Upon receipt of the design from the Client we liaise with a specialist machining company who we subcontract to form the blank tool. Once in receipt of the 75mm blank router we clean and coat the 30mm tip in a coarse grade diamond grit which is used to form ventilation holes in helmets.

- Manufacture blank tool to design and apply diamond grit to specification — GRP/ ceramic kitchen and bathroom manufacturing company:

- Upon receipt of the design from the Client we liaise with a specialist machining company who we subcontract to form the blank tool. Cut to various sizes we clean and coat the tip of the router cutter in a coarse grade diamond grit which is used to form waste and overflow holes in baths and sinks.

Get in Touch

If you have a query or would like to get any further information on what we can offer, don’t hesitate to reach out using the contact information below or send a message using the form.

Address

Unit 25b, Tir Llwyd Industrial Estate, Kinmel Bay, Rhyl, North Wales LL18 5JA

Telephone – 07799847899

Email – martin@adept-tooling.com

Where you’ll find us

Enquiry form